Matt Tallman has always loved beer. He homebrewed, and when he travelled, he would seek out breweries to visit. Just as important as the beer itself, he enjoyed the social aspects and camaraderie of it.

This was fundamental in shaping what would become Trans Canada Brewing Company (TCB), which Tallman founded and owns today. While the first beer would not be brewed until 2017, planning started in 2015. His goal was to create beer and a space that would welcome everyone.

“We want you to come here to enjoy our products and our atmosphere,” said Emma Houldsworth, brand and marketing leader at the brewery. “We welcome all ages, we have long, communal picnic tables and the room is one large space, instead of being sectioned off. We want it to feel like an extension of hanging out with friends and family in the backyard.”

The TCB taproom has 16 draft beers on tap and offers cider from Dead Horse Cider Co. and wine from Low Life Barrel House (both local producers), along with non-alcoholic beer from Partake Brewing and a variety of sodas.

“We have a simple mission: to offer a beer for everyone,” said Houldsworth. “From seasoned craft beer enthusiasts who seek out bold, hop-forward IPAs, to someone who enjoys the easy drinkability of a crisp, clean lager, there’s a TCB beer made with you in mind. Every beer we produce is developed, brewed and packaged entirely in-house. This hands-on approach allows us to maintain complete control over quality, from recipe development to the final pour, ensuring every can that leaves our brewery reflects our high standards and dedication to the craft.”

The staple of the taproom food menu is pizza, with a core lineup of 12 favourites, as well as two feature pizzas per month, both of which have a suggested beer pairing. That list of pizzas is supplemented by other shareable items like artichoke dip, sliders and tacos. Almost everything on the menu is meant to be shared, furthering the brewery’s goal of fostering community.

Since the release of Batch No. 001 in 2017, we’ve set aside a portion of each annual brew from Foeder No. 5 and bottle it, knowing a part of the original 2017 brew lives on.

Scott Sawatzky, Trans Canada Brewing Company

The taproom has live music on Fridays and Saturdays, and it is always subtle to ensure the taproom is welcoming to all. “We want to be a reliable brand, so whether we are the go-to spot for a night out with family and friends, or the beer that is always stocked at home, we want our customers to know they can expect the same level of care we put into every aspect of our company,” said Houldsworth.

Great beer

The 16 draft beers in the taproom consist of five core beers and rotating seasonal beers brewed on TCB’s 35-hectolitre brewhouse, which feeds into 14 70-hectolitre fermenters. TCB also has a five-hectolitre research and development brewery for experiments and recipe development, but the brewery eschews gimmicks.

“We want to give our customers proven winners,” said Houldsworth. The brewery uses its small brewhouse to aquire feedback from taproom customers when developing new beers, all with the intention of developing and improving their beer line up.

“Every October, we get together and plan what the entire following year will look like for beer launches, [including] what they are, when they’re coming out, how much we plan to make and what the beer will be packaged in,” said Scott Sawatzky, TCB’s senior leader of operations. “This is a full-team effort involved in our launch calendar, including our production team making and packaging the beer, input from our sales team with what they experience in the market and asking our taproom team what they hear from our customers.”

For beer lovers seeking a more elevated experience, TCB has a fleet of six 40-hectolitre foeders and a collection of barrels. “Our anniversary beer, Solera Farmhouse Saison, which was actually the first beer ever brewed at TCB, is made in a foeder,” said Sawatzky. “Since the release of Batch No. 001 in 2017, we’ve set aside a portion of each annual brew from Foeder No. 5 and bottle it, knowing a part of the original 2017 brew lives on.

“Good beer always starts with good ingredients. You can have the best equipment, the most creative recipe or the most skilled brewers, but if the ingredients aren’t top quality, the beer won’t be either.” To that end, TCB builds relationships with trusted suppliers, looking to local and Canadian sources whenever possible. “Our Flying Otter Light Lager is a great example. It’s brewed with Canadian malt barley grown right here on the Prairies,” said Sawatzky.

We want to be a reliable brand, so whether we are the go-to spot for a night out with family and friends, or the beer that is always stocked at home, we want our customers to know they can expect the same level of care we put into every aspect of our company.

Emma Houldsworth, Trans Canada Brewing Company

Another beer he’s proud of is Harvest Sky, which TCB releases every fall to line up with the end of the harvest season. “What makes it special is that every ingredient comes from Manitoba or Saskatchewan, from the malt to the hops. It’s a small way for us to celebrate the farmers and producers who help make what we do possible,” said Sawatzky.

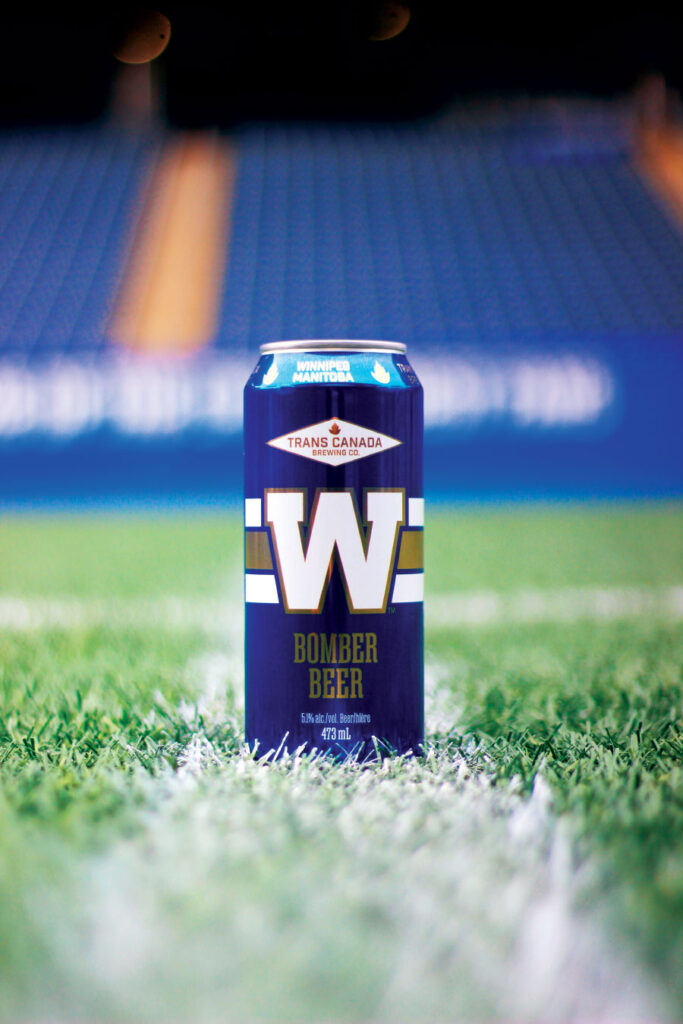

TCB beer can be found across Manitoba, including every Liquor Mart in the province, as well as independent local beer vendors, restaurants and bars. “We really try to make sure we’re showing up wherever our customers are looking for us. We want to be easy to find,” said Will Lisson, TCB president.

Great community

“[TCB] is proudly independently owned and operated right here in Manitoba,” said Lisson. “That independence is something we deeply value, not just as a point of pride, but as a strategic advantage. It gives us the freedom to make decisions quickly, stay rooted in our community and remain true to our vision.”

Staying rooted in the community means investing in that community outside of the taproom as well as inside. “We’re proud to support causes that matter to our community and our province,” said Houldsworth. “Most recently, and hitting close to home, we started a new initiative to help raise funds for those affected by the Manitoba wildfires. All proceeds in June from our Scooper Pale Ale, which features a water bomber aircraft as the main illustration, [were] donated to the Canadian Red Cross for Manitoba wildfire relief.”

Within TCB, community is fostered by promoting a team approach where every employee is valued. “We believe strong leadership means setting a clear direction, while also listening actively, supporting professional development and trusting our team to take ownership of their roles,” said Lisson.

“That’s what drives our growth and helps us build an engaged company culture. Our leadership is focused on empowerment and collaboration. We intentionally foster a culture where every team member, whether they’re on the production floor, in the taproom or at the leadership table, feels encouraged to contribute ideas, ask challenging questions and take initiative. Innovation doesn’t just come from the top down; it comes from creating space for ideas to rise organically through every level of the organization.”

Great future

In the eight years since opening its doors to the public, TCB has achieved growth and success by being a part of, and helping to build, the Winnipeg beer scene and broader community. That growth has now provided an exciting opportunity.

“We are in the process of starting our expansion into Brandon, Man., with our second taproom and brewery,” said Houldsworth. “Brandon was an easy choice for our first expansion opportunity. It’s an exciting city, and the surrounding areas represent a huge market that has only recently started its craft beer journey. We aspire to be a household name in the beer industry in Manitoba, and Brandon allows us to speak directly to customers in a … new [way].”

Planning for TCB’s Brandon expansion is well underway, with an opening date scheduled for 2026. That new location will have the same community feel as the existing Winnipeg taproom, but with its own taproom-exclusive offerings, supplemented with beer from the main production facility, which will remain in Winnipeg.

“As for our Winnipeg location, we are always thinking of ways we can continue to evolve and improve. [We’ve started] some light planning on taproom renovation and upgrades, and expanding our production side. We are consistently growing and doing what we can to be the best version of ourselves, not only for our customers, but for our team.”