Getting into the drinks business can be an expensive venture. Manufacturing equipment, packages, labels, insurance and permits to operate are just some of the many requirements to start producing a beverage. These costs scare away many would-be entrepreneurs from launching their drinks business.

Luckily, contract manufacturing provides a safer alternative to launching and testing a drink brand, without the investment of setting up a production facility.

What is contract manufacturing?

Contract manufacturing is when an existing production facility, such as a brewery or distillery, enters a partnership with another business to manufacture a product on their behalf. The beverage product is sold under the other business’s brand name. These beverages are often called “shadow brands” since the business does not have its own brick-and-mortar space.

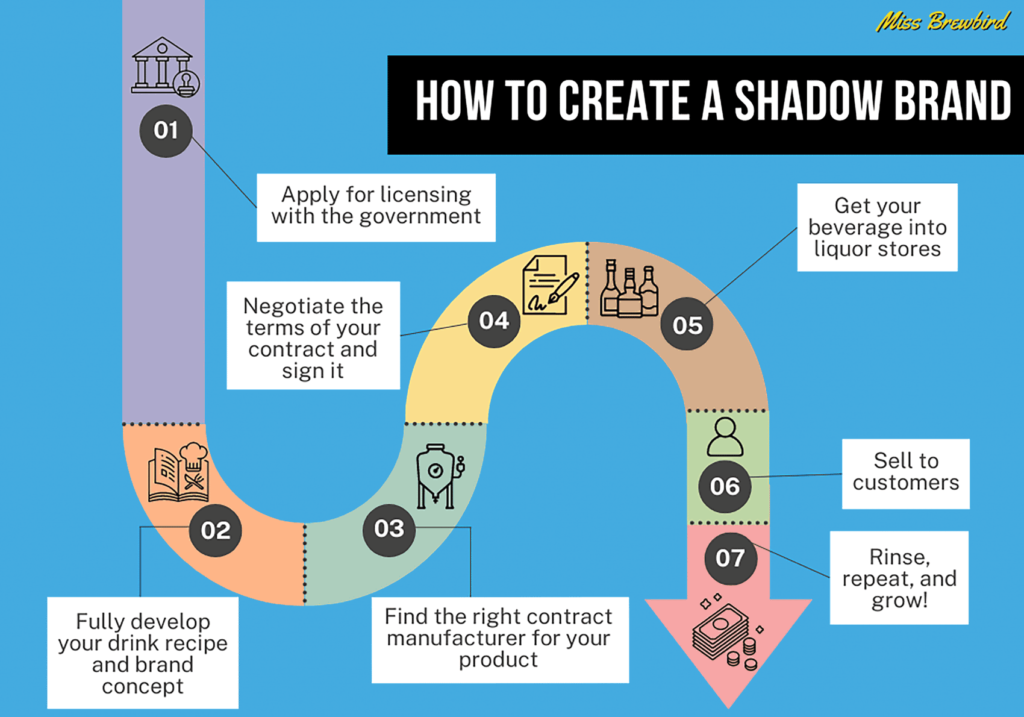

Steps to create a shadow brand

In British Columbia, Russell Brewing Company has been contract brewing off and on for six years. They usually take contracts from existing Vancouver breweries who seek to fulfil production gaps. Steve Schafer, general manager at Russell Brewing Company, outlined the steps involved in creating a shadow brand for an alcoholic beverage.

Step 1: Apply for licensing with the government

A shadow brand must register with the appropriate government bodies. In B.C., these are the B.C. Liquor Distribution Branch and the B.C. Liquor and Cannabis Regulation Branch.

Schafer says that the shadow brands Russell Brewing works with are required to apply for their own manufacturing licenses. This may seem counter-intuitive since the shadow brand is not actually manufacturing anything. However, the manufacturing license allows the products to be registered under the brand owner’s license rather than the production facility’s license, and the shadow brands retain proprietary ownership of their products.

Schafer estimates that applying for a manufacturing license can take 18 to 24 months, and says that the process is more difficult for brands that don’t have a manufacturing facility. He notes that establishing a shadow brand for alcoholic products is quite an investment, since the production and distribution of alcohol is heavily regulated by the Canadian government.

Step 2: Fully develop the drink recipe and brand concept

What type of drink will be made? Will the drink be packaged in cans or bottles? What makes the drink unique? These are just some of the many questions shadow brands need to answer when developing a product.

A shadow brand should have a clear vision of their product before approaching contract manufacturing facilities since it is difficult to make changes to a product once manufacturing begins.

No two contract manufacturing facilities are the same. Some facilities have bottling equipment, while others only have canning equipment. Shadow brands need to find a manufacturing facility that can produce the product they envision.

Step 3: Find the right contract manufacturer for the product

No two contract manufacturing facilities are the same. Some facilities have bottling equipment, while others only have canning equipment. Shadow brands need to find a manufacturing facility that can produce the product they envision.

Along with ensuring that the facility can produce their product, the shadow brand will need to determine if the manufacturing facility can produce their beverage at a cost that enables them to make a profit. The cost of manufacturing is highly dependent on production requirements. For instance, ready-to-drink products, such as canned cocktails, usually only require mixing and can be packaged within a few hours.

Beer, on the other hand, requires brewing, mashing and fermenting, spanning several weeks to produce. Fermenting beer also requires tank storage. All these factors add to manufacturing costs. The size and production parameters of the manufacturing facility will also dictate the minimum order quantity.

Step 4: Negotiate the terms of the contract and sign it

A shadow brand must determine the details of their contract with the manufacturer. For example, some shadow brands purchase their own labels, while others will ask their contract manufacturer to purchase labels on their behalf. Manufacturers may be able to get a better deal since they order in bulk and often have larger discounts with suppliers.

Another important detail to consider in the contract is where the product will be stored. Contract manufacturers may be able to store the finished product for the shadow brand if they have the space, or the shadow brand may need to arrange for another storage space. Keep in mind that alcoholic products must be stored in a bonded warehouse. Shadow brands can apply for a bonded warehouse or hire another company to store and distribute their product.

Step 5: Get the drink into liquor stores

Once the beverage is manufactured, it’s time to get it into liquor stores. Shadow brands can hire liquor brand representatives to approach liquor stores to carry their product.

When first approaching liquor store managers, bring product sell sheets or product samples to help managers decide whether they want to carry the product. Keep in mind that liquor store owners often ask for free bottles or additional perks for purchasing the product. Establishing a good rapport with liquor store employees and managers may help sell more products, since employees can recommend the product to customers. This in turn can lead better shelf placement for the product. Generally, products placed at eye level tend to sell better than products placed very high or very low.

Step 6: Sell to customers

The work has only just begun once a shadow brand gets its product onto liquor store shelves. They will need to develop a marketing plan to spread the word about their amazing new product.

This can entail creating a website and social media accounts for the brand. They can run online ads and promotions for their beverage, set up a booth at farmers’ markets and offer free tastings at liquor stores. It is all about getting the product in front of people and converting them into paying customers.

Step 7: Rinse, repeat and grow!

Once a shadow brand starts making sales and they are confident the product will continue to sell, they can go back to their contract manufacturer to make more product.

As the drink brand continues to grow, they may even think of establishing their own brick-and-mortar manufacturing facility.

Weighing the pros and cons of starting a shadow brand

Establishing a shadow brand is a safer and less expensive way to start a drinks business. The main benefits for contract manufacturing a product are the cost savings and required expertise to operate a manufacturing facility.

“[Shadow brands] are not putting up the money to build and facilitate production, but at the same time they have to pay for that,” said Schafer. “Either they are paying perhaps more than they hoped, and their margin is shrinking and they’re getting [more] quality, or they can pay less and not get the quality that they were expecting…. It is a balance of cost versus quality.”

Shadow brands are also reliant on contract manufacturers to have the capacity to produce their products. During the busy summer season, manufacturing facilities may be operating near or at maximum capacity. So, either they might not be able to get their product made, or the price goes up compared to slower months when the facility has spare capacity.

Another important detail to consider in the contract is where the product will be stored. Contract manufacturers may be able to store the finished product for the shadow brand if they have the space, or the shadow brand may need to arrange for another storage space.

Successful shadow brands usually transition from using a contract manufacturer to owning their own manufacturing facility over time, since owning a manufacturing facility allows the brand greater quality control, more reliable production schedules and higher profit margins.

Overall, contract manufacturing is an excellent way to test a drink concept, and to determine whether it is worth investing more time and effort.

Kristine Hui is a professional distiller who has made whisky, gin and liqueurs in distilleries in the U.K., India and Canada. She helped to develop a rum recipe, which won a Silver medal at the 2021 International Wine and Spirits Competition. Most recently, she appeared as a contestant on Moonshiners: Master Distiller on the Discovery Channel. She is best known as Miss Brewbird on YouTube, where she documents her work in fermentation.